Easy entry into the IIoT with audako

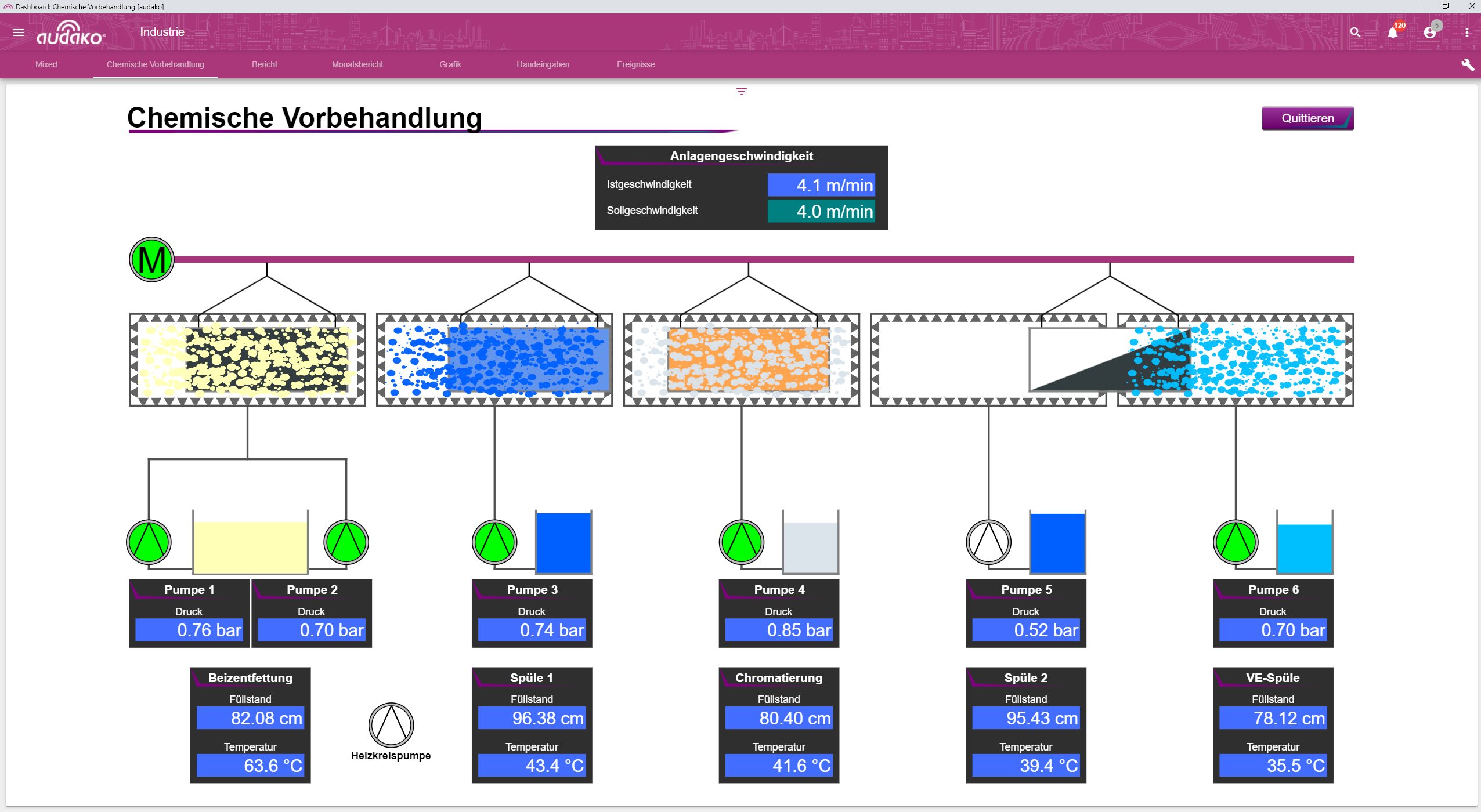

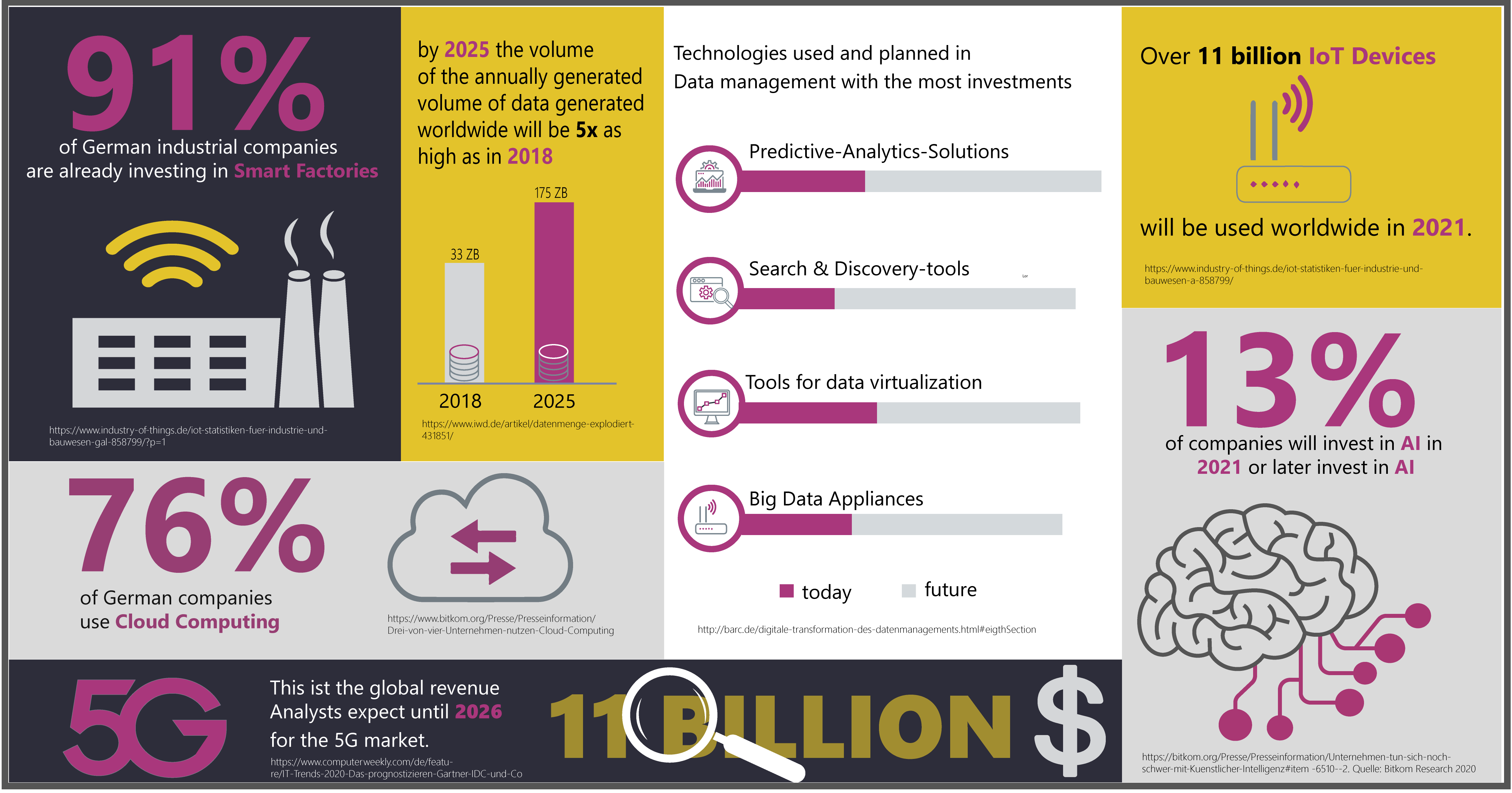

With the help of audako, whether in the cloud or on your own server, you can start your digitization project in record time - always accessible from anywhere in the world. Audako IoT Gateways already process data locally and support the latest 5G standard today. Our experience in production-critical areas offers you professional support from process consulting to the integration of solutions tailored to your needs. The flexibility of audako allows you to quickly and easily implement your IIoT applications into existing processes. With audako, you can see in real time what exactly is happening in your production, in the warehouse or in individual plants. You can increase the efficiency of industrial processes, reduce production costs and develop new digital business models.

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/PC_Teileverwaltung_Wartung.png)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/PC_Verknuefte_Aufgaben.png)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/PC_Wartung.png)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/PC_Wartung_Aufgaben_Dokumente_Ersatzteile.png)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/PC_Wartungseintraege.png)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/Loesung_Industrie_Feature5.png)